Tuyauterie

Nous avons acquis une grande expertise dans le domaine de la tuyauterie industrielle. Notre but premier est de vous donner un service de qualité supérieure au plus bas coût possible, et ce, dans un milieu de travail sécuritaire, quel que soit l’ampleur et le rythme de production de votre entreprise.

Nous travaillons avec la tuyauterie de tout diamètre et de matériaux divers tels que l’acier au carbone, le cuivre, l’acier inoxydable, l’aluminium, l’Inconel, le PVC et le CPVC. Nous offrons également le service de piquetage en charge (Hot tap).

Nous offrons le service d’installation et de réparation de tuyauterie pour diverses composantes. Nos employés sont qualifiés pour effectuer des travaux sur les tuyaux contenant de l’eau, de l’air comprimé, de la vapeur, du gaz, du diesel, du caustique, du gaz naturel, du biogaz, de la résine, du phénol, de l’acide et plusieurs autres matières. Nos soudeurs sont qualifiés et expérimentés pour effectuer de la soudure haute pression.

Nous fabriquons aussi des supports standards et sismiques, et faisons des tests hydrostatiques, aux rayons X et autres. Notre personnel peut prendre en charge vos travaux, que ce soit pour un projet à prix fixe ou de type temps-matériel.

Des professionnels à votre portée!

Mécanique

Nous avons une vaste expérience en mécanique industrielle pour les industries lourdes. Nous savons que votre rythme de production est important et faisons tout en notre pouvoir pour régler vos problèmes dans les plus brefs délais.

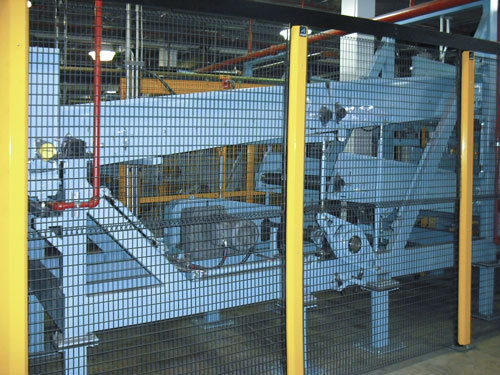

Nos mécaniciens industriels et chaudronniers sont expérimentés et polyvalents. Que ce soit pour l’entretien, la modification, la manutention ou l’installation de vos équipements quels qu’ils soient, et peu importe leur poids, nous avons l’expertise et l’outillage nécessaire pour effectuer tous vos travaux.

Nous effectuons l’installation de lignes de production, de convoyeurs de tous types, de pompes, d’agitateurs et autres. Notre personnel peut prendre en charge vos travaux, que ce soit pour un projet à prix fixe ou de type temps-matériel.

Qu’il s’agisse de « grosse mécanique » ou de mécanique qui demande un ajustement de précision au millième, nous avons le personnel qualifié pour votre projet. Nous offrons des services allant de la conception à l’installation, incluant la fabrication de vos pièces sur mesure. Nos spécialités incluent également l’alignement de précision, les systèmes de convoyeurs, les équipements de procédés, la manutention d’équipement et la relocalisation d’usine.

Confiez-nous vos tâches!

Arrêt d'usine

Nous savons que les frais reliés aux arrêts de production sont significatifs, et c’est pour cette raison que nous mettons en place les effectifs requis afin de nous assurer du respect des échéanciers et contraintes de nos clients.

Nous avons l’expertise et les effectifs nécessaires pour planifier, superviser et exécuter vos travaux de mécanique et de tuyauterie durant un arrêt d’usine. Nous savons que l’approvisionnement rapide en outillage et matériaux est une priorité pendant un arrêt d’usine afin de respecter les échéanciers. C’est pourquoi nous mettons les effectifs nécessaires pour s’assurer de répondre aux besoins très rapidement.

CCR Mécanique inc. est un partenaire indispensable pour vous aider à planifier vos arrêts d’usine ou vos déménagements. Nous avons une équipe de contremaîtres et des surintendants expérimentés en planification, préparation et exécution d'arrêts d'usine et de déménagements selon les normes de qualité et de sécurité les plus élevées.

Faites appel à des professionnels, vous économiserez temps et argent!

Un service rapide et efficace!

Structure

Nous offrons le service de fabrication, d’installation et de réparation de structures de toutes sortes. Quelle que soit la structure dont vous avez besoin pour votre industrie lourde, nous avons les ressources nécessaires à sa réalisation.

Notre personnel est qualifié pour exécuter tous vos travaux d’acier tels que les plateformes, les escaliers, les échelles, les passerelles, les renforcements de structure et les supports pour équipements ou tuyauterie.

Nos employés détiennent les formations nécessaires pour la manutention de ces structures et ce, même dans des situations particulières ou contraignantes demandant plus de vigilance. Soyez assurés que nous mettons tout en place pour protéger les équipements à proximité et garder l’environnement intact.

Nous effectuons une étude des risques potentiels pour tous les projets de structure, et mettons en place les procédures pour assurer un travail sécuritaire.

C’est du solide!

Fabrication en atelier

Nous offrons le service de fabrication de tuyauterie, de modules et de supports sur mesure, dans notre atelier. Ce service permet d’accélérer le processus de réalisation d'un projet et d’amoindrir les coûts de production.

Les ateliers contiennent tout l'outillage nécessaire pour la fabrication de vos structures et équipements, ce qui économise du temps de transport et de fabrication.

Notre équipe est formée pour effectuer les relevés sur le chantier ou en usine et faire les dessins isométriques. Nous réalisons des bancs d’essai hydrostatiques, en plus d’effectuer des travaux d’estimation, de peinture et de livraison de matériel.

La fabrication en atelier est la solution idéale pour pallier le manque d’espace en usine et pour gagner du temps!

Des outils adaptés à votre réalité!